Programmable logic controllers (PLCs) first hit the scene in the late 1960s. The primary reason for designing such a device was to eliminate the large cost involved in replacing the complicated relay-based machine control systems for major U.S. car manufacturers.

Some companies proposed schemes based on the Digital Equipment Corp. DEC PDP-8, the widely-used mini-computer at the time. Dick Morley’s company Bedford Associates in Massachusetts proposed something called a Modular Digital Controller (MODICON).

The MODICON 084 brought the world’s first PLC into commercial production. Since then, slow steady growth has allowed the manufacturing and process control industries to take advantage of PLC applications-oriented software—programmable language that looks and feels like relay-ladder-logic where any maintenance technician.

INVENTION OF PLC

In 1969, Dick Morley was running a small business out of a garage and serendipitously built the first PLC. He humbly states, “We were building it and didn’t know we were building it.” Morley kept the relay design simple with four outputs, and the automotive manufacturers snapped up the technology. In the early days, Morley said the automotive companies wanted to purchase the PLC at an ever-declining price. Although Morley was skeptical about the viability of the business long-term, a colleague convinced him to take the deal as the real money to be made in PLC was in the repair and maintenance of systems once they were implemented. Four years later, in 1973, Michael Greenburg designed the first commercially successful PLC, which was further developed by Modicon to replace relay-based technology for both General Motors and Landis.

PLCs use ladder logic and essentially bring to life physical relays, timers, and wired connections. By eliminating the requirement for rewiring and new hardware for every additional logical configuration, PLCs drastically boosted the functionality of controls without adding to the physical space required for additional hardware and equipment. However, the original PLCs had little memory capability, could not handle off-site inputs and outputs, and needed proprietary terminals for new programming.

Morley is generally credited with the “invention” of the PLC. However, there were many others involved in the birth of this landmark development, including the late Odo Struger (from Allen-Bradley, now Rockwell). Morley said details of the PLC came about on 1 January 1968. Some 35 years later, it is arguably the most widely used product in the industrial automation business, with a worldwide market of several billion dollars per year. PLC products are available from hundreds of different sources, in many different form-factors (including embedded controllers), and with prices ranging from tens of thousands of dollars (for triple redundant, failure-proof systems) to commodity products at less than a hundred bucks.

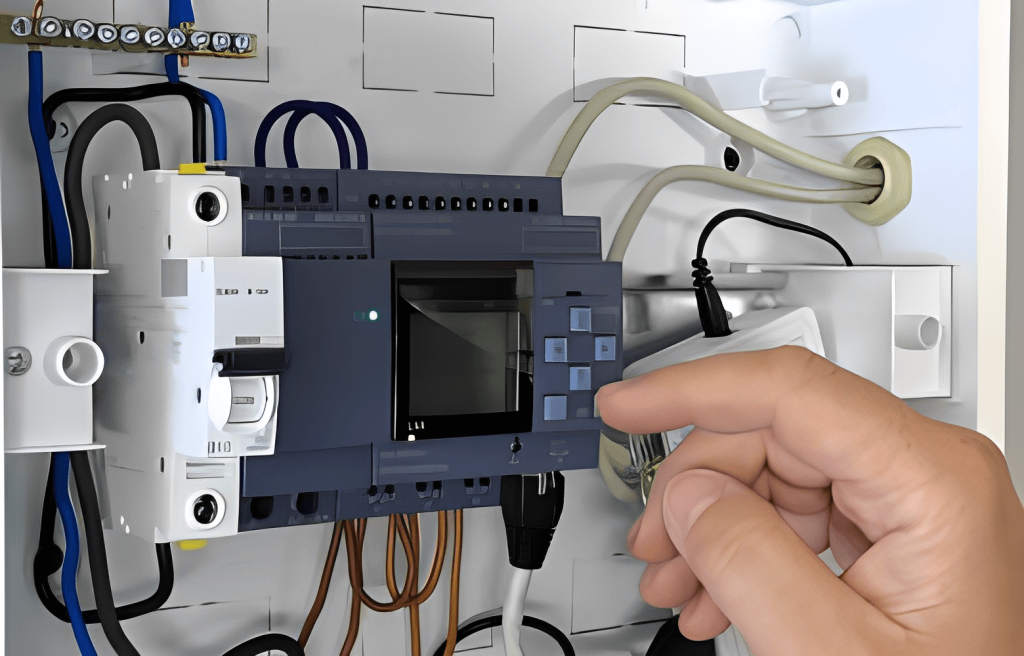

The emergence of the first PLC in 1968 meant large banks of relays could be replaced by a single device that was easier to maintain and could be programmed with the already accepted relay ladder logic. In addition, the PLC was equipped with enough memory to retain loaded programs in the event of power outages and was also designed to operate in industrial environments where dirt, moisture, electromagnetism, and vibration were often present. Having a PC communicating with a PLC provided the ability to not only program but also allow easier testing and troubleshooting.

Communications started with the MODBUS protocol using RS-232 serial communications. The addition of various automation protocols communicating over RS-485, Device Net, Profibus, and other serial communication architectures have followed. The use of serial communications and the various PLC protocols also allowed PLCs to be networked with other PLCs, motor drives, and human-to-machine interfaces (HMI). Most recently Ethernet and protocols such as Ethernet/IP (for Industrial Protocol) have gained tremendous popularity.

Conclusion

PLC technology has a long history within industrial companies, providing a breakthrough tool that has helped businesses become more efficient in managing their equipment, processes, and systems over the years. As the technology has advanced, complementary tools have evolved, allowing industrial companies to expand their use and applications of PLC throughout an entire facility. As smaller and medium-sized companies continue to compete in the global marketplace, they will increase their use of PLC and related technologies to grow and thrive in the future.

fAQS

Looking for answers to your frequently asked questions about PLCs? Look no further! Dive into our comprehensive FAQ section below to find everything you need to know about Programmable Logic Controllers, from basic concepts to troubleshooting tips and more.

What are the components of a PLC?

The PLC consists of a central processing unit (CPU), input/output (I/O) modules, a power supply, and a programming device.

Why was PLC invented?

The first programmable logic controllers were developed as a solution to replace large banks of hardwired relays and timers. At the time, using relays and timers for applications that are now handled by PLCs posed numerous challenges.

Where are PLCs used?

PLCs are used in various applications in industries such as the steel industry, automobile industry, chemical industry, and the energy sector. The scope of PLCs dramatically increases based on the development of all the various technologies where it is applied.

Fathima Sadina works as a Technical Associate at IIPD, where she dives into the world of Industrial Automation, focusing on PLC, SCADA, and VFD systems. With a keen passion for spreading know-how, she loves to craft engaging blog posts on a wide array of technical subjects.